NT PUMPEN

NT PUMPEN Pumped liquid Pure water, industrial water, sea water, condensate, oils, brines, lyes, hot water. The liquids to be

CIRCOR ist die Muttergesellschaft der folgenden Unternehmen:

ALLWEILER, HOLZGARTEN, IMO, TUSHACO, WARREN, ZENITH.

ALLWEILER ist einer der führenden Anbieter von Pumptechnologien von Weltklasse.

Der älteste deutsche Pumpenhersteller, gegründet 1860.

Die Allweiler GmbH ist eines der führenden Unternehmen auf dem europäischen Markt für Technologien und Lösungen für den Umgang mit Flüssigkeiten für den Schiffbau, die Stromerzeugung und spezielle industrielle Anwendungen. Die Produktpalette ist in der Branche konkurrenzlos und umfasst Kreiselpumpen, Propeller, Schraubspindel, Peristaltik, Propeller, Kraftstoff, mehrstufige und mehr.

Als Mitglied der CIRCOR hat die Allweiler GmbH Zugang zu bedeutenden Finanz- und Fertigungsressourcen, allen Forschungs- und Entwicklungsressourcen der Gruppe, Produktionskapazitäten sowie Vertrieb und Service. Personal ist weltweit verfügbar.

Schiffe, Schiffsanlagen, Kraftwerke, Öl-, Gas- und Kraftstoffindustrie, Wassersysteme, Bewässerung, Pumpen aus Brunnen, chemische Industrie, Wärmeübertragung, Werkzeugmaschinen, Bauindustrie, Karton- und Papierindustrie, Pharmazeutika, Lebensmittel.

internationaler Standards: Zertifizierung

| DIN EN ISO 9001 |

| Lloyd`s Register Quality Assurance All of ALLWEILER’s plants and the foundry are certified according to DIN EN ISO 9001 |

| DIN EN ISO 14001 |

| Eco-audit and environmental management system Every employee is required to act in an environmentally-conscious manner. |

| ISO 45001 |

| ISO 45001 ISO 45001 |

| ISO 50001 |

| ISO 50001 ISO 50001 |

| ATEX compliance |

| EU directive 94/9/EG – ATEX 100a Safely enter the new era of elevated explosion protection with ALLWEILER pumps. |

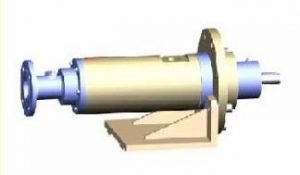

NT PUMPEN Pumped liquid Pure water, industrial water, sea water, condensate, oils, brines, lyes, hot water. The liquids to be

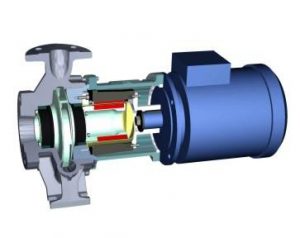

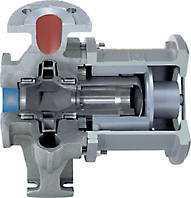

Volute Casing Centrifugal Pump in in-line design up to PN 10 Pumped liquid Pure water, industrial water, sea water, condensate,

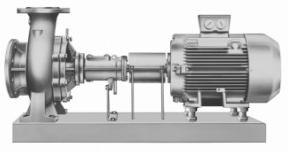

Volute Casing Centrifugal Pump in block design up to PN 10 Pumped liquid Pure water, industrial water, sea water, condensate,

Propeller pump for horizontal or vertical installation, PN 6 Pumped liquid For handling with non-aggressive or aggressive fluids, uncontaminated or

Volute Casing Centrifugal Pump in in-line design up to PN 10 Pumped liquid For handling fresh water, Sea water, condensate,

Volute Casing Centrifugal Pump in block design up to PN 10 Pumped liquid For handling fresh water, Sea water, condensate,

Volute Casing Centrifugal Pump in in-line design up to PN 10 Pumped liquid Fresh water, sea water, condensate, oils, brines,

Volute Casing Centrifugal Pump in block design up to PN 10 Pumped liquid Fresh water, sea water, condensate, oils, brines,

Volute Casing Centrifugal Pump for lube oil supply, immersed Pumped liquid Lube oils Main fields of application Main lube oil

Volute Casing Centrifugal Pump in block design up to PN 10 Pumped liquid Fresh water and sea water. The fluids

Volute Casing Centrifugal Pump, double suction, in in-line design, PN 10 Pumped liquid For handling fresh water, Sea water, condensate,

Volute Casing Centrifugal Pump in base plate design up to PN 16 Pumped liquid Organic heat transfer oils Main fields

Volute Casing Centrifugal Pump in in-line design up to PN 16 Pumped liquid Organic heat transfer oils Main fields of

Volute Casing Centrifugal Pump in block design up to PN 10 Pumped liquid Organic heat transfer oils Main fields of

Volute Casing Centrifugal Pump in base plate design up to PN 25 Pumped liquid Organic heat transfer oils Main fields

Volute Casing Centrifugal Pump in in-line design up to PN 25 Pumped liquid Organic heat transfer oils Main fields of

Volute Casing Centrifugal Pump in block design up to PN 25 Pumped liquid Organic heat transfer oils Main fields of

Volute Casing Centrifugal Pump with Magdrive in block design up to PN 16 Pumped liquid Aggressive fluids, full desalinated water

Volute Casing Centrifugal Pump with Magdrive in base plate design up to PN 16 Pumped liquid Aggressive fluids, full desalinated

Volute Casing Centrifugal Pump with Magdrive in block design up to PN 16 Pumped liquid Organic heat transfer oils Main

Volute Casing Centrifugal Pump with Magdrive in in-line design up to PN 16 Pumped liquid Organic heat transfer oils Main

Volute Casing Centrifugal Pump with Magdrive in base plate design up to PN 25 Pumped liquid Heat transfer liquids, water

Volute Casing Centrifugal Pump with Magdrive in block design up to PN 25 Pumped liquid Aggressive fluids, full desalinated water

Volute Casing Centrifugal Pump with Magdrive in base plate design up to PN 25 Pumped liquid Aggressive fluids, full desalinated

Volute Casing Centrifugal Pump in base plate design up to PN 25 Pumped liquid For handling aggressive or non aggressive,

Volute Casing Centrifugal Pump in block design up to PN 25 Pumped liquid For handling aggressive or non aggressive, cold,

Volute Casing Centrifugal Pump for lube oil supply,immersed Pumped liquid Lube and sealing oil, hydraulic oil Main fields of application

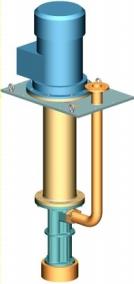

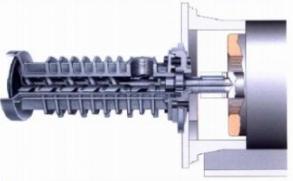

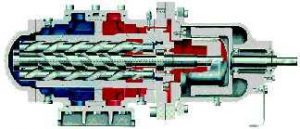

Three-Screw pump up to 16 bar, vertical submerged installation Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating oils

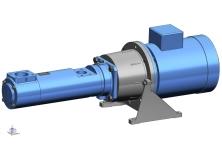

Three-Screw pump for applications up to 100 bar Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating oils Main

Three-Screw pump for low flow rates and 100 bar Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating oils

Three-Screw pump for high pressure applications up to 160 bar Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating

Three-Screw pump for high pressure applications up to 210 bar Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating

Three-Screw pump for applications up to 13 bar Pumped liquid For handling lubricating liquids without any abrasive components in particular

Three-Screw pump for applications up to 13 bar Pumped liquid For handling lubricating liquids without any abrasive components in particular

Three-Screw pump for applications up to 16 bar Pumped liquid For handling lubricating liquids without any abrasive components in particular

Three-Screw pump for applications up to 16 bar Pumped liquid For handling lubricating liquids without any abrasive components in particular

Three-Screw pump for applications up to 13 bar Pumped liquid For handling lubricating liquids without any abrasive components in particular

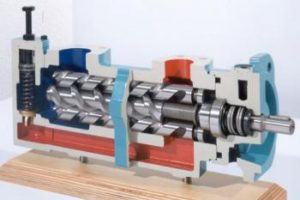

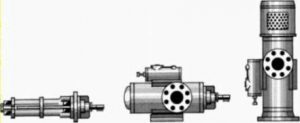

Three-Screw pump for general applications up to 100 bar Pumped liquid Chemically neutral, lubricating, e.g., fuel oils, lube oils, hydraulic

Three-Screw pump for general applications up to 120 bar Pumped liquid Chemically neutral, lubricating, e.g., fuel oils, lube oils, hydraulic

Three-Screw pump for high pressure applications up to 280 bar Pumped liquid Chemically neutral, lubricating, e.g., fuel oils, lubricating oils,

Three-Screw pump for applications up to 40 bar Pumped liquid For handling lubricating liquids without any abrasive components in particular

Three-Screw pump for non lubricating fluids Pumped liquid Non- or mal-lubricating, slightly abrasive, corrosive Main fields of application Process engineering,

Volute Casing Centrifugal Pump in base plate design up to PN 16 Pumped liquid Organic heat transfer oils Main fields

Volute Casing Centrifugal Pump in in-line design up to PN 16 Pumped liquid Organic heat transfer oils Main fields of

Volute Casing Centrifugal Pump in block design up to PN 10 Pumped liquid Organic heat transfer oils Main fields of

Three-Screw pump for applications up to 90 bar Pumped liquid Oil-in-water emulsions, grinding oils, cutting oils, collant lubricant solutions Main

Three-Screw pump Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating oils Main fields of application For generation of

Three-Screw pump for lifting system Pumped liquid Hydraulic oils, synthetic hydraulic liquids, native oils, lubricating oils Main fields of application

Three-Screw pump with Magdrive up to 64 bar Pumped liquid Toxic, harmful to the environment, highly volatile, explosive, non-abrasive as

Three-screw screw pump with magnetic coupling for applications up to 40 bar. Pumped liquid For handling lubricating liquids with no

Progressing Cavity Pump in block design with feed screw up to 12 bar Pumped liquid For handling highly viscous or

Progressing Cavity Pump with double feed screw up to PN 25 Pumped liquid For handling highly viscous or non-flowable, neutral

Progressing Cavity Pump in base plate design up to 12 bar, with feed screw Pumped liquid For handling highly viscous

Progressing Cavity Pump in base plate design up to PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral

Progressing Cavity Pump in block design up to PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral or

Progressing Cavity Pump in base plate design up to PN 25 Pumped liquid Low to highly viscous liquids, pasty, neutral

Progressing Cavity Pump in block design up to PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral or

Progressing Cavity Pump in block design up to PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral or

Progressing Cavity Pump in block design with feed screw up to 12 bar Pumped liquid For handling highly viscous or

Progressing Cavity Pump in base plate design up to PN 64 Pumped liquid Low to highly viscous liquids, pasty, neutral

Progressing Cavity Pump in block design up to PN 25 Pumped liquid Low to highly viscous liquids, pasty, neutral or

Progressing Cavity Pump in base plate design up to PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral

Progressing Cavity Pump in block design up to PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral or

Progressing Cavity Pump in base plate design up to 12 bar Pumped liquid Low to highly viscous liquids, pasty, neutral

Progressing Cavity Pump in block design up to 12 bar Pumped liquid Low to highly viscous liquids, pasty, neutral or

Progressing Cavity Pump in block design, mobile by chassis frame Pumped liquid Pure water, maische, alcohol, wine, juice, milk, lyes,

Peristaltic Pump for high pressure application, PN 16 Pumped liquid Low to highly viscous liquids, pasty, neutral or aggressive, pure

Propeller Pump, vertical submerged Pumped liquid Wastewater, activated sludge Main fields of application Commonly applied as recirculating pumps for digesters,

Progressing Cavity Pump for dosing applications up to 12 bar Pumped liquid Low to highly viscous liquids, pasty, neutral or

Pumped liquid Pure water, industrial water, sea water, condensate, oils, brines, lyes, hot water. The liquids to be pumped must

Since 1990 Rexima Industrie Equipment GmbH supplies technical products and solutions of